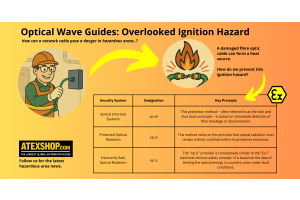

How Fibre Optic Cables Pose A Risk In Explosive Atmospheres

Optical fibers are commonly used for data transmission in industrial environments, particularly when cable runs exceed 100 meters and copper Ethernet is no longer viable. The general assumption is simple: once installed, the cable does its job – transmitting data from point A to B – and that's it. There is a common opinion that there are no special requirements for data transmission via fiber optics. Especially in hazardous areas, this assumption is not only persistent but is potentially dangerous.

The common belief is that optical wave guides (OWGs) are inherently safe because they transmit light rather than electrical current. As such, they are frequently installed without additional precautions, under the impression that they pose no ignition risk. System operators often express surprise when questioned about safety standards for fibre optics in hazardous environments, pointing out that such systems have been operating for years without incident.

However, this is actually a big misconception! While the light itself – with the exception of powerful blue lasers – does not carry enough energy to ignite a gas-air mixture, it can still heat particles or surface deposits to ignition temperature of the locally present gas if a cable is damaged, spliced incorrectly or disconnected without care. In an explosive atmosphere, even a small heat source can trigger an explosion.

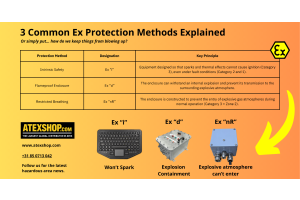

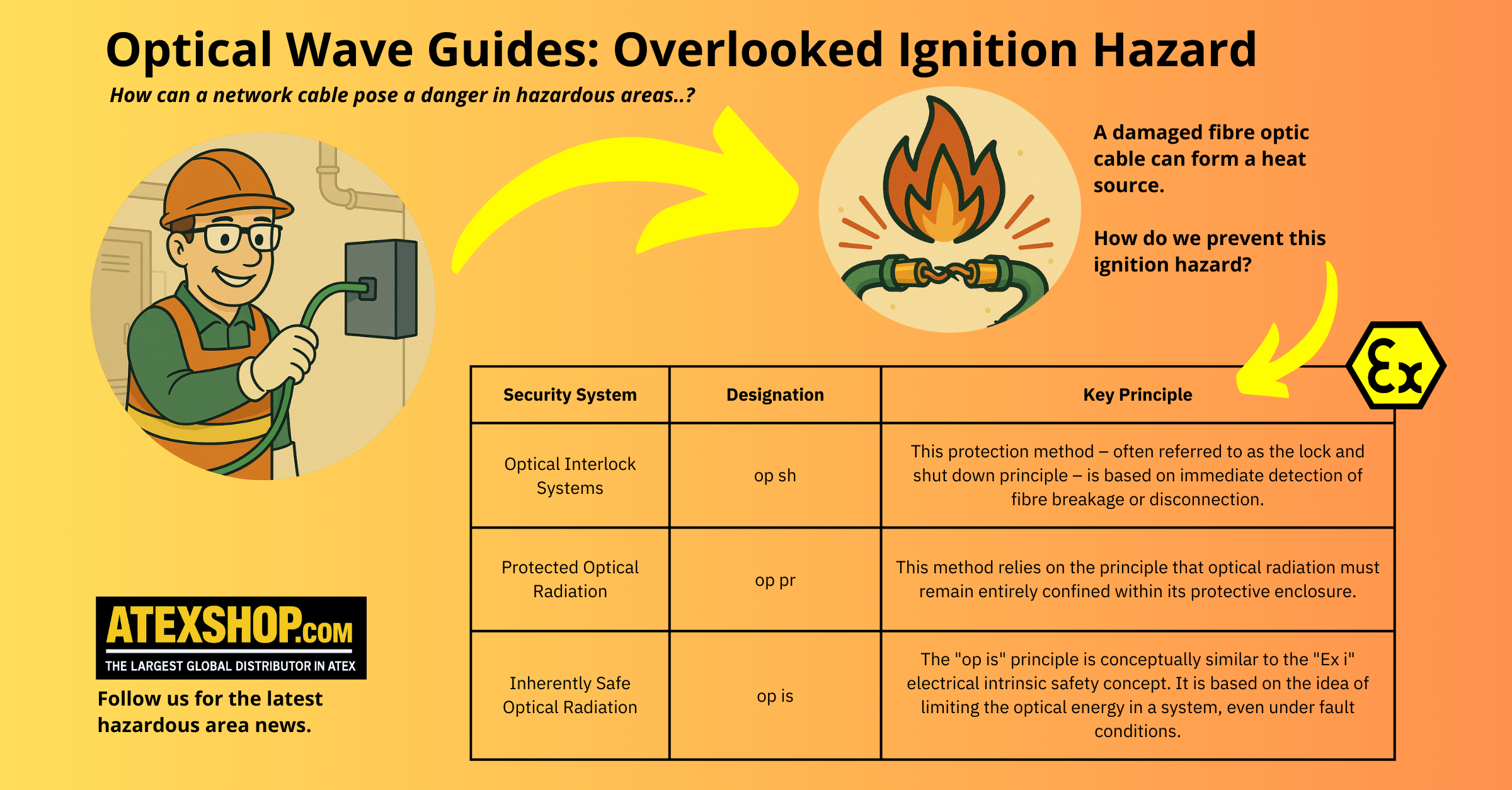

To address this, the IEC/EN 60079-28:2015 standard sets clear requirements for the use of optical radiation in explosive atmospheres. It defines three recognized protective concepts:

op sh (Optical Interlock Systems)

This protection method – often referred to as the lock and shut down principle – is based on immediate detection of fibre breakage or disconnection. Once a fault is identified, the system safely shuts down the optical radiation, preventing hazardous exposure to light energy in the explosive atmosphere. The implementation of “op sh” is heavily reliant on functional safety concepts.

Due to these special requirements, there are very few products available on the market that support this type of protection. They are typically used in laboratory environments or small test facilities where a sudden system shutdown does not lead to costly production stoppages.

Important note: The "op sh" concept is not suitable for industrial production environments. In large-scale plants, unplanned and sudden shutdowns can lead to significant and, above all, costly process interruptions or even safety risks.

op pr (Protected Optical Radiation)

This method relies on the principle that optical radiation must remain entirely confined within its protective enclosure. In other words, light must not escape into the hazardous atmosphere under any circumstances.

To achieve this, fibre optic cables must either be designed to be mechanically robust or be routed in a manner that protects them from destructive influences. Enclosures used in this protection concept must meet the same standards as those in “increased safety” (Ex e) or “flameproof encapsulation” (Ex d) explosion protection. That means no transparent elements such as glass windows or discs are allowed – these could allow dangerous levels of radiation to escape during a fault.

All external connections – especially those located in Zone 1 – must comply with applicable standards such as DIN EN 60079-0, including the use of certified cable entries and connectors. The expansion and laying of fiber optics takes place within protected systems.

A complete "op pr" implementation often requires the use of rigid piping systems or other containment solutions along the entire fiber route to ensure continuous protection along the entire route. The high planning effort, as well as the complex implementation, can sometimes be expensive. The passage through different fire compartments and the balancing of different potentials must be taken into account.

op is (Inherently Safe Optical Radiation)

The "op is" principle is conceptually similar to the electrical intrinsic safety concept "Ex i". It is based on the idea of limiting the optical energy in a system – such as a fiber optic line – in such a way that an explosive atmosphere cannot ignite even under fault conditions.

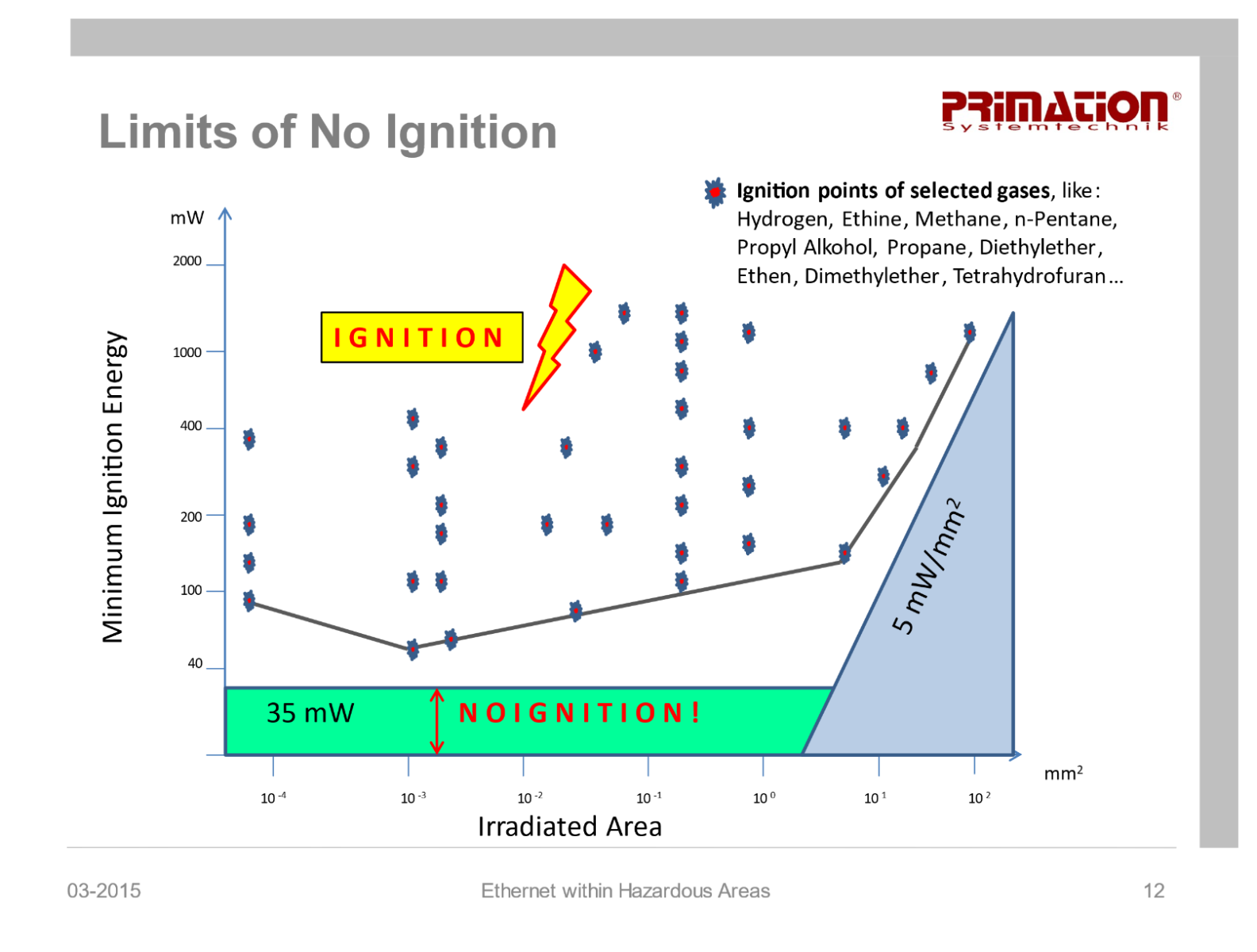

In Zone 1 areas and for explosion group IIB in temperature class T4, the maximum permissible optical power is 35 mW. Falling below this performance limit ensures that no gas-air mixture can ignite, even if the cable is damaged or the light beam is focused on a small area. Additional restrictions apply to the use of pulsed radiation; These are covered in Appendix E of the second edition of IEC 60079-28, which provides a detailed flowchart for the evaluation of impulse safety.

Alternatively, the irradiance – defined as optical power (mW) per irradiated area (mm²) – must not exceed 5 mW/mm². Reducing cable cross sections or altering fibre geometry can concentrate light output and must be avoided, as this could unintentionally increase ignition risk.

The “op is” protection concept is particularly advantageous for Industrial Ethernet installations in hazardous areas. Because optical fibers do not carry electrical current, they can also be connected or disconnected under voltage in Zone 1, providing excellent flexibility in installation and maintenance. This reflects the advantages of electrical intrinsic safety, where live maintenance is possible due to the limited energy available

To ensure continuous compliance:

- Optical transmitters must have integrated power limiting modules on both the transmit and receive sides. This also applies to the power supply; In this case, there must be no pulse peaks in the optical transmission in the event of overvoltage or undervoltage.

- No design changes should allow the energy of other connected fibers to increase the total radiated power beyond safe thresholds.

- The fiber optic line must be secured in both directions, as we have a transmitting and receiving line here.

What can you do to prevent danger?

One example of this approach in practice is the P-Ex-OTR opis range from PRIMATION Systemtechnik. These media converters include built-in safety circuitry to meet the op is requirements. Their compact format makes them suitable for both new installations and retrofitting into existing systems.

In short, while fibre optic cables are often perceived as completely risk-free in explosion-prone areas, that is only true under certain conditions. Proper protective measures – particularly those defined by IEC/EN 60079-28 – should be applied to avoid introducing a hazard where none was expected.

For HSE personnel and IT departments working in hazardous environments, reviewing optical data transmission systems against these standards is a necessary part of ensuring long-term operational safety. Do you have any doubts? Feel free to reach out to the ATEXSHOP.com team for advice.